Autosked is kind of a quirky product. The code base started life as a tee time management system for Portland golf courses. A golf-playing exec from a local car dealership asked if software could be modified to manage customer appointments in his lube / oil change bays. And Autosked was born. Many years later, the package is still used at many dealerships where it is viewed as indispensable.

Autosked is kind of a quirky product. The code base started life as a tee time management system for Portland golf courses. A golf-playing exec from a local car dealership asked if software could be modified to manage customer appointments in his lube / oil change bays. And Autosked was born. Many years later, the package is still used at many dealerships where it is viewed as indispensable.

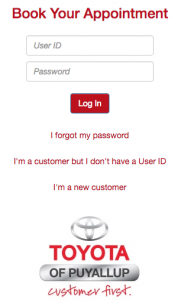

My contribution has been to write two new dealer management system (DMS) interfaces and create a web app for consumers to schedule their own appointments. You can see that at work here at one customer’s site. This is a single page app that uses a lot of javascript and Bootstrap.

The DMS interfaces are a combination of php, Unix shell scripts and C programs.

In addition, I’ve been taking steps to bring more best practices to the development process at the company.