![]() This project was for a station monitor to tie multiple pieces of equipment to factory-wide WIP tracking and process control system using a C program. The connection allowed analysis of data collected from the line width measurement system to be use to fine tune the lithography tools in the cluster.

This project was for a station monitor to tie multiple pieces of equipment to factory-wide WIP tracking and process control system using a C program. The connection allowed analysis of data collected from the line width measurement system to be use to fine tune the lithography tools in the cluster.

Tag Archive: Factory Automation

Host Interface for Fab Equipment Cluster

Fab Process Interfaces

I did numerous projects over several years in Silicon Valley at Intel, Sematech and AMD with a product called Streamline made by project lead Bayliss Automation.

I did numerous projects over several years in Silicon Valley at Intel, Sematech and AMD with a product called Streamline made by project lead Bayliss Automation.

Streamline made making interfaces to SECS II compatible equipment much easier than doing so with raw C code. These interfaces were to etchers, furnaces, wet stations, ion implanters and deposition systems.

The work of hooking up a new piece of gear was in characterizing how well it conformed to the SECS II specification and then implementing the kind of control and monitoring desired by the process engineers. The languages I used were C and Streamline.

GEM Host Interface

Semiconductor fab equipment needs to provide an interface to factory automation systems. A local company was making planarizers for a new Intel factory and I got the opportunity to help with this SECS II interface. The design encapsulated the Generic Equipment Model (GEM) functionality in a VBX control for use by an existing Visual Basic machine controller application. The functions included recipe download, process monitoring and material handling. For the project I used C++ and VB.

Semiconductor fab equipment needs to provide an interface to factory automation systems. A local company was making planarizers for a new Intel factory and I got the opportunity to help with this SECS II interface. The design encapsulated the Generic Equipment Model (GEM) functionality in a VBX control for use by an existing Visual Basic machine controller application. The functions included recipe download, process monitoring and material handling. For the project I used C++ and VB.

Metrology Station Monitor

Finding problems and optimizing process requires collecting and analyzing data after each step of wafer fabrication. These interface modules were for various CD, thin film and resistivity measurement equipment. Working for Bayliss Automation, I specified and wrote a Windows-based application for data acquisition and alarm logging. The product, called a Metrology Station Monitor, was implemented for several customers across the US.

Finding problems and optimizing process requires collecting and analyzing data after each step of wafer fabrication. These interface modules were for various CD, thin film and resistivity measurement equipment. Working for Bayliss Automation, I specified and wrote a Windows-based application for data acquisition and alarm logging. The product, called a Metrology Station Monitor, was implemented for several customers across the US.

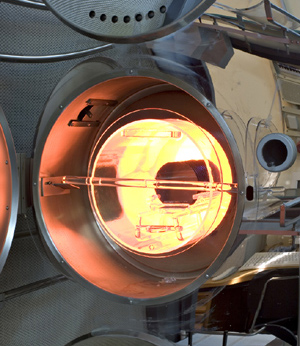

Monitoring System for Plasma Etcher

Etchers remove material from unmasked areas of a wafer. It’s critical to stop the etching at just the right moment. This is done by measuring the composition of the gas in the chamber. Optimal etch recipes can be determined by examing graphs of the gas composition. I built an Excel-based monitoring system, using the SECS II protocol. As wafers were processed, a real-time graph was displayed and the data stored and uploaded to the factory host. The system was used at Intel’s Fab 1 in Santa Clara.

Etchers remove material from unmasked areas of a wafer. It’s critical to stop the etching at just the right moment. This is done by measuring the composition of the gas in the chamber. Optimal etch recipes can be determined by examing graphs of the gas composition. I built an Excel-based monitoring system, using the SECS II protocol. As wafers were processed, a real-time graph was displayed and the data stored and uploaded to the factory host. The system was used at Intel’s Fab 1 in Santa Clara.